Exploring the Duration: Unraveling the Timeframe Needed to Craft a Plastic Medical Mold

In the fast-paced world of medical device manufacturing, precision and efficiency are key. From the fledgling ideas to the final product, every step matters in the medical injection molding process. Here's a breakdown of the phases, from design to mass production, along with their typical durations:

Phases of Medical Injection Molding

- Concept Development (1-2 weeks) In this initial stage, designers and engineers collaborate to create detailed designs, considering factors such as material choice, geometry, and manufacturing requirements to optimize the design for medical injection molding.

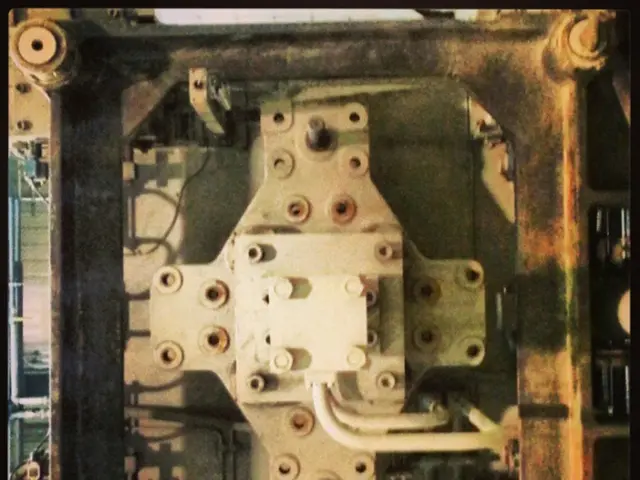

- Mold Fabrication (2-4 weeks) Once the design is locked in, the mold is fabricated using precise machining or 3D printing techniques. Depending on factors like intricacy, dimensions, and available tools, the fabrication timeline may vary. State-of-the-art technologies like Computer Numerical Control (CNC) machining and additive manufacturing expedite the mold fabrication process.

- Mold Testing and Validation (1-2 weeks) Before the actual production can kick off, the newly manufactured mold undergoes rigorous testing and validation. This ensures the mold is an exact fit for the medical injection molding process. Testing may involve trial runs with prototype materials, dimensional checks, and performance assessments.

- Production Setup (1-2 weeks) With the mold passing all tests, it’s time for production setup. This includes readying the injection molding machine, selecting suitable materials, and tuning parameters like temperature, pressure, and cycle time. Quality control measures are also established to maintain consistency throughout the production process.

- Mass Production (Ongoing) After production setup, mass manufacturing can commence. The mold, filled with molten plastic material, forms the finished product. Routine quality checks are conducted throughout to ensure compliance with industry standards and requirements.

Additional Insights on Medical Injection Molding:

- Advantages:

- Consistency and Precision: Injection molding delivers unparalleled precision, guaranteeing uniformity and consistency.

- Flexibility: The process allows for the creation of complex geometries, fostering innovation and functionalities in medical devices.

- Cost-Effectiveness: While setup costs may be higher compared to other manufacturing methods, economies of scale in mass production result in lower per-unit costs in the long run.

- Material Variety: Injection molding uses a wide range of materials, ensuring that medical device manufacturers can choose the ideal material for their application, considering factors like biocompatibility, sterilization, and transparency.

- Challenges:

- Regulations: Medical devices face stringent regulations, necessitating compliance with standards such as ISO 13485 and FDA regulations throughout the entire injection molding process.

- Material Compatibility: Selecting appropriate materials is critical to ensure material compatibility and adherence to regulatory requirements.

- Tooling: The lifespan and quality of the mold significantly impact the molded product's quality and consistency. Regular maintenance and inspection are crucial to extend mold life and minimize production downtime.

- Risk Management: Addressing inherent risks like material degradation, tool wear, and process variability is paramount to ensure the production of high-quality medical devices.

- Project Timeline: The overall timeline for the medical injection molding process varies depending on the project's complexity, regulatory requirements, and mold type. A conventional metal mold may take 8-12 weeks to produce, while rapid or prototype molds can be made in as little as 2-4 weeks. After mold fabrication, additional time is required for mold testing/validation, production setup, and mass production validation, with the total duration spanning several weeks to a few months, or possibly longer, depending on potential regulatory hurdles.

Sources:[1] https://www.premierplastics.com/insights/what-is-injection-molding/[2] https://www.invatech.com/injection-moulding/mould-making-process/conventional-vs-rapid-injection-moulding/[3] https://www.designnews.com/3d-printing/sneak-peek-at-siemens-process-chain-for-plastics-part-36216[4] https://www.moulding-expert.com/injection-moulding-steps/

In the realm of medical device manufacturing, the science of material selection plays a crucial role in meeting health-and-wellness standards, ensuring biocompatibility and sterilization compliance for medical conditions. With the advances in health-and-wellness technology, the variety of materials available for injection molding enables medical device manufacturers to cater to diverse needs, from transparency to addressing specific medical conditions. However, navigating medical-condition-related regulations, maintaining material compatibility, and managing the risks involved in the injection molding process can pose challenges that require meticulous planning and execution.